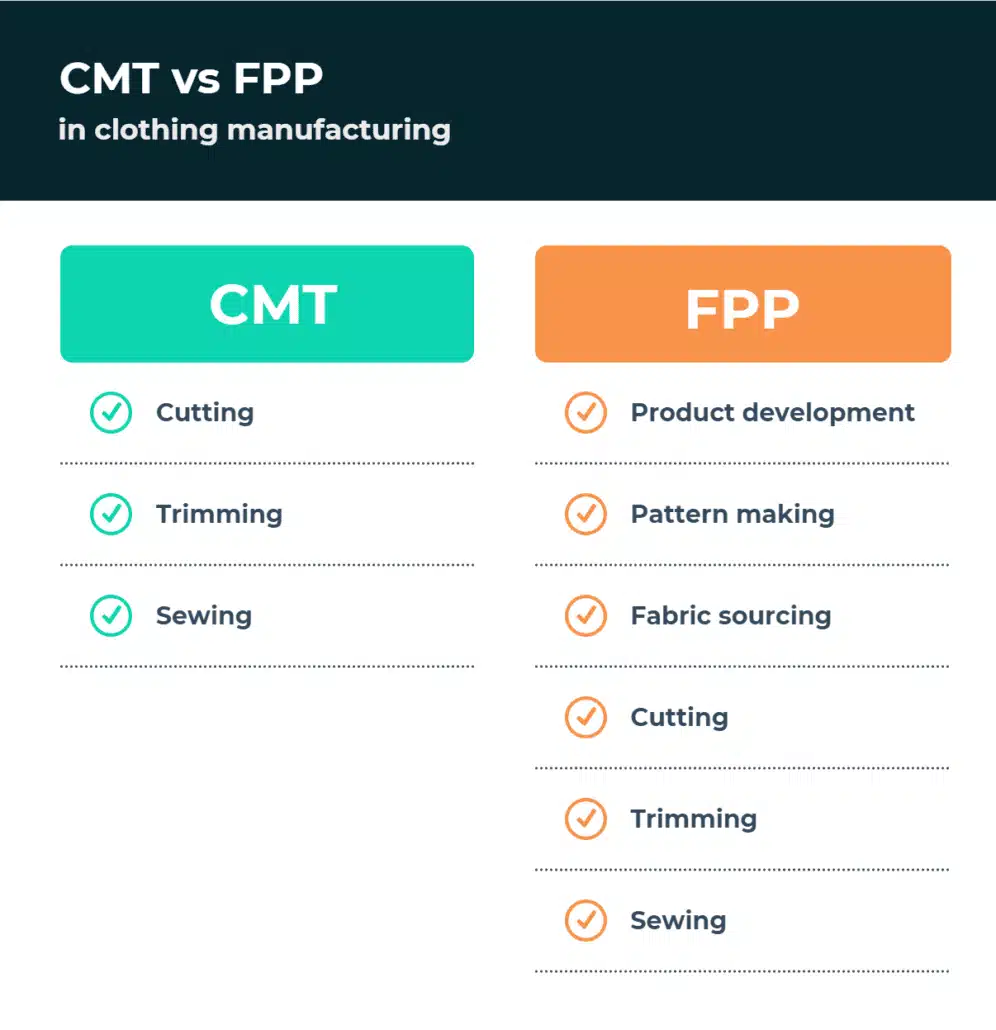

In the apparel manufacturing industry, “CMT” stands for “Cut, Make, and Trim.” It is a term used to describe a type of manufacturing process or service provided by garment manufacturers or contractors.

Here’s what each component of CMT represents

Embarking on a journey into the garment industry often involves navigating through a landscape of industry jargon, and one such term is CMT. An acronym with significant implications, CMT represents a crucial aspect of clothing manufacturing. In this exploration, we will unravel the meaning behind each component of CMT and understand its pivotal role in the intricate process of bringing clothing from concept to reality. Join us as we demystify the world of CMT and delve into its integral elements.

Cut

This refers to the process of cutting the fabric according to the pattern pieces. The fabric is usually cut in bulk based on the required quantities.

Make

This stage involves assembling the cut fabric pieces together to create the garment. It involves sewing tasks like stitching, attaching buttons or zippers, adding labels, and other essential components

Trim

The final step of the CMT process involves finishing touches and adding the finishing details to the completed garment. This can include tasks like hemming, pressing, quality control checks, and packaging.

CMT is a common outsourcing model used by clothing brands or retailers.

Brands often outsource parts of the manufacturing process, like fabric cutting or sewing, to specialized contractors.CMT (Cut, Make, Trim) allows brands to focus on design, marketing, and distribution, leveraging the efficiency of specialized garment manufacturers in production.

The Benefits of CMT in the clothing manufacturing

There are several benefits of utilizing the Cut, Make, and Trim (CMT) model in clothing manufacturing:

Cost-effectiveness

CMT allows clothing brands to control costs more effectively. By outsourcing specific stages of the manufacturing process to specialized contractors, brands can avoid the need for large-scale infrastructure, equipment, and skilled labor. Smaller or emerging brands, lacking resources for in-house production, can achieve significant cost savings.

Flexibility and scalability

CMT offers flexibility and scalability in production. Brands can adjust their production volumes according to demand without the need for major investments in machinery or labor. As CMT manufacturers specialize in specific production stages, they can efficiently accommodate variable order sizes and timelines, allowing brands to respond quickly to market trends and customer preferences.

Expertise and specialization

CMT manufacturers typically specialize in specific stages of the production process. This means they have a high level of expertise, experience, and efficiency in their respective areas. By partnering with these specialized manufacturers, brands can benefit from their knowledge, skills, and streamlined processes, ensuring better quality control and faster turnaround times.

Focus on core competencies

Clothing brands Focusing on core competencies like design, marketing, and distribution is achievable by outsourcing the manufacturing process to CMT contractors. This enables them to allocate more time, resources, and attention to areas where they can add the most value to their products and brand identity.

Reduced production lead times

CMT manufacturers often have well-established supply chains and efficient workflows. This can lead to reduced production lead times as they can quickly source raw materials, perform specific production tasks, and deliver finished goods. This agility can be advantageous for brands aiming to launch new collections or respond to fast-changing market demands promptly.

Clear specifications, design guidelines, and regular communication are crucial to ensure the desired product outcome and maintain consistent quality standards throughout the manufacturing process.

In the apparel manufacturing industryIn the apparel manufacturing industry

Finding the right manufacturer for CMT Work

Finding the right manufacturer for Cut, Make, and Trim (CMT) work requires careful research and evaluation. Here are some steps to help you in the process:

Define your requirements

Start by clearly defining your product requirements, including the type of sportswear, materials, production quantities, quality standards, and any specific manufacturing processes involved.

This will help you narrow down manufacturers that specialize in your specific needs.

Research and compile a list

Conduct thorough research to identify potential manufacturers who offer CMT services.

Use online directories, industry trade shows, referrals from industry contacts, and search engines to compile a list of manufacturers that align with your requirements.

Request for samples or portfolio

Request samples of their previous work or ask for a portfolio showcasing their expertise in sportswear manufacturing. Evaluate the quality, craftsmanship, and attention to detail in the samples to ensure they meet your expectations.

Communication and transparency

Engage in open communication with potential manufacturers. Ask questions about their processes, lead times, pricing structure, and ability to accommodate your specific needs. Assess their responsiveness and willingness to collaborate.

Visit the facilities

If possible, schedule a visit to the manufacturing facilities of shortlisted manufacturers. This will allow you to observe their production processes firsthand, assess their working conditions, and meet their team.

It gives important information about their abilities, how efficiently they produce, and whether they are a good fit as a partner.

Start with a small order

Choosing a manufacturer and beginning with a small production run or trial order is recommended.

Finding the right manufacturer for CMT work is crucial for the success of your Apparel production.

Take the time to thoroughly evaluate and compare manufacturers based on their capabilities, experience, quality, pricing, and alignment with your specific requirements.

apparel manufacturing